Products

Qlok

Advanced Materials

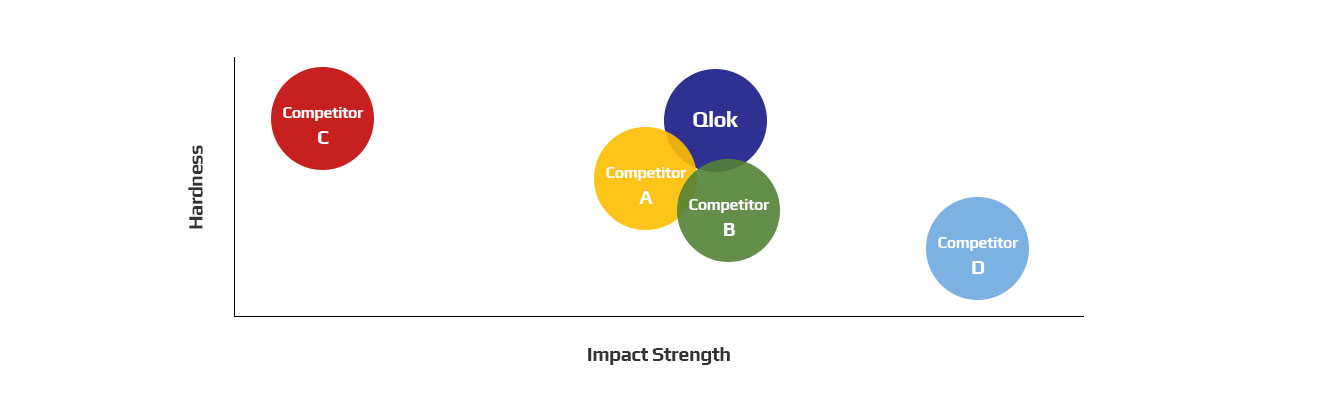

- Application of SBIC's proprietary new material with excellent balance between hardness and impact strength

- Excellent abrasion resistance and impact resistance compared to competitive materials (alloy design optimized for the purpose of use)

- Stable material quality through automated heat treatment process and strict quality control

- Verification of superiority compared to competitor materials through actual use data in various tests and fields

- Mechanical Properties

- TS, YS, El, Hardness, CVN

- Wear Resistance

- Sand Abrasion Test(ASTM G65)

TYPE

-

SA510 / Tooth, Shroud

Optimal combination of high hardness

(for wear resistance) and excellent impact strength (for system robustness) -

SA410/ Adapter, Heel Shroud

Ensuring proper hardness and excellent impact strength for alloy design with adequate weldability and excellent impact resistance

-

ASTM G65 Sand Abrasion Test

Mechanical Properties

Comparison of Mechanical Properties between SBIC New Alloy and Competitors

Advantage

-

Hammerless Locking SystemDecrease Down Time

- · Easy & Safe : Hammeriess

- · Reliable

- · Reusable Locking Parts

-

SBIC Superior MaterialsDecrease Maintenance Cost

- · High Wear Resistance

- · High Impact Strength

- · Extending Useful Life

-

Optimum Shape DesignIncrease Machine Productivity

- · Various Option

- · Efficient Work

- · Extending Useful Life

Field Test Overview

-

Test period

- From April, 2018 to present (more than 40 months)

- Total test time (cumulative) over 10,000 hours

-

Machine

- Total 8 excavator

-

HITACHI EX3600, EX2600, EX1900, ZX870, ZX470

KOMATSU PC2000, PC1250, CAT 532F, HCE R8000 etc.

-

Used GETs

- Tooth : over 500 parts

- Adapter : over 100 parts

-

Test Field

- South Korea, Finland, Indonesia

- Granite Quarry, Road Construction Site, Coal Mine